Swiss Precision Machining

In choosing fresh goods layouts and manufacturing techniques, businesses must consider rapid production, component manufacturing, and durability. Numerous machining choices are more accessible to businesses now than ever before. CNC Swiss devices, also known as CNC Swiss machines for turning, are among the most significant decisions, particularly for producing small components. Three of the most crucial factors to consider for your subsequent endeavor involving microscopic parts are manufacturing pace, the effectiveness of materials, and accuracy. Discover the advantages of CNC Swiss precision machining centre machining over other milling techniques for producing small parts.

Accuracy:

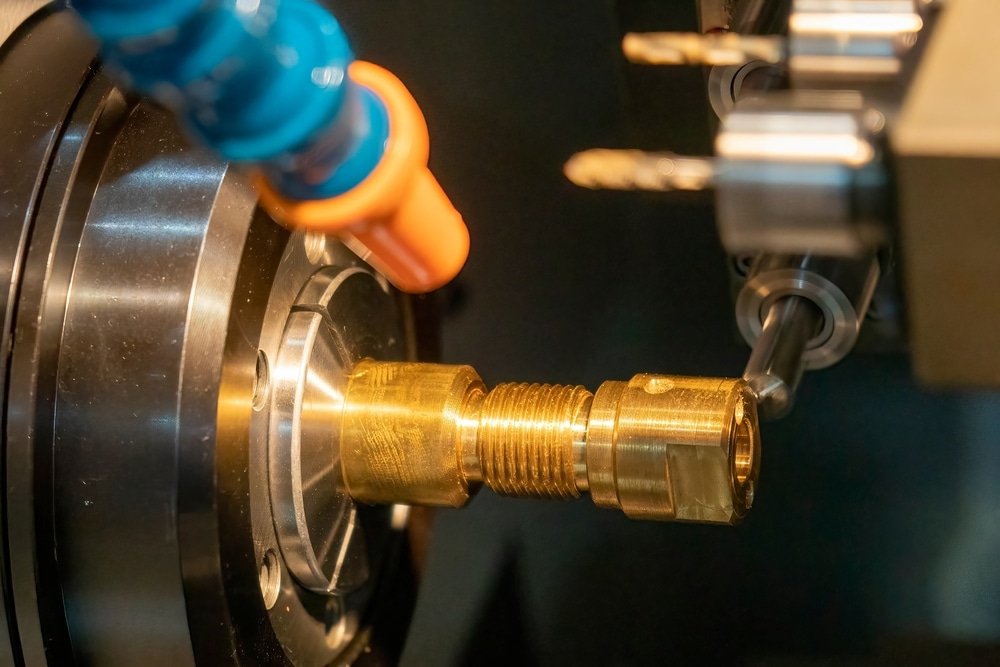

However, the CNC Swiss turning machine is highly exact regarding intricate and tiny parts. The devices use a guiding suspension that supports the component in place, providing a firm grip and enabling the cutting instruments to strike the material at precisely the correct angle and place. Companies use these devices to create parts that adhere to strict design requirements and exceedingly precise specifications. It will convert the design documents into a sequence of manufacturing commands by CNC machinery on CNC Swiss turning machine tools. There is minimal unpredictability and no chance of human mistake because the live equipment follows the guidance precisely.

Sub spindles:

Sub-spindles are another characteristic of Swiss machine tools that enable the device to create more intricate, multi-featured pieces in just one turn. It used to take a great deal of effort and time to build complicated components with complicated shapes without making mistakes. NC Swiss spindle manufacturing may now be relied upon by almost any industry to fulfil various requirements. The automotive, aerospace, and healthcare sectors—all of which need high-precision components—benefit greatly from it.

Efficiency of Materials:

The majority of companies and their clients aim for elevated material effectiveness. Swiss CNC turning centers are perfect for cutting down on wasteful production, which lowers expenses and makes a company more environmentally friendly. Swiss manufacturing uses guiding bearings and stiff machinery to reduce bends. These characteristics produce precise tolerances and flawless results in any manufacturing functioning, including pressing, cutting, veering, tapping, and grinding.

Speed:

Efficiency is another essential advantage of Swiss turning centers. Companies occasionally complete large orders in a remarkably short Amount of time. Quick processing speeds, less time spent on technical or human tasks, and minimal setup pauses result from the mainly robotic processes. The following four factors are essential to the rapid manufacturing speeds:

Minimal Delays during Constant Bar-Feeding:

Producers continually feed Massive bars of stuff into the equipment using CNC Swiss milling. They save time by not having to transport and retrieve individual parts, which reduces availability and increases output.

Rapid Spindle Turns and Rates:

The number of spinning components for Swiss machining centers reaches 10,000–15,000 RPM. Compared to traditional CNC milling machines, this is around threefold speedier. Production times and milling procedures speed up because of these higher rates.

Machining on multiple axes:

Multiple dimensions are a common characteristic of CNC Swiss machine tools. It significantly streamlines the manufacturing procedure by enabling the lathe to perform cutting actions on the component simultaneously.

Shorter Startup Times:

Software that explains how the device will generate various characteristics on the component for each new task. It will shorten the duration of manufacturing by using the identical code for each consecutive manufacturing run. Faster changeover between programs is possible by reducing the setup period.

CNC Machine Shop Manufacturing Services:

Small-part CNC turning centers have several essential benefits, such as increased efficiency in manufacturing, dependability, speed, and waste reduction. Our specialty at our company is offering top-notch machining services that produce exact items for a range of vital sectors. You can also search “CNC Machine Near Me” for more information.

Contemporary Swiss Machine CNC Shop Equipment Improvements:

A large selection of spinning instruments and the distinctive design of the device’s tool area are two other benefits that the Swiss manufacturing centre offers. Numerous Swiss small-scale manufacturing machines use live instruments, which removes the requirement for additional steps for complicated parts and may hold over twenty resources in the machining region. Furthermore, it lessens the chip-to-chip duration to a second or shorter because of the equipment’s tight geometry, which enables the device to operate in mm of the material.