1. The Development of Vietnam’s CNC Industry

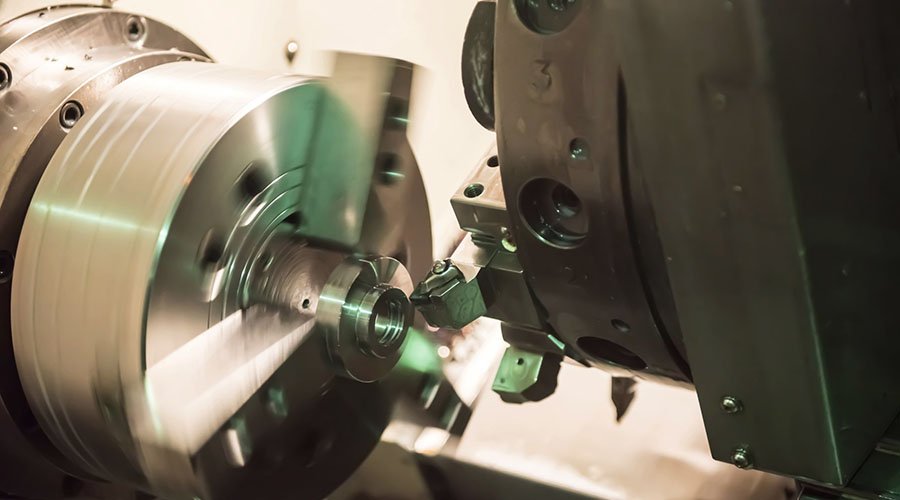

In recent years, Vietnam has been striving to develop and establish itself as a leading hub for precision CNC machining in the region. Thanks to the government’s proactive approach in international integration and strong investment promotion in CNC technology, Vietnamese enterprises are gradually asserting their position in the global market, particularly in supplying precision mechanical components to the U.S. market.

1.1. Strengths of Vietnam’s CNC Industry

- Skilled workforce and low labor costs: Vietnam’s workforce is increasingly receiving formal training with high expertise, combined with specialized CNC programs at vocational schools and universities. A team of skilled engineers and workers ensures continuous improvement in precision machining quality.

- Rapidly developing technical infrastructure: Vietnam has been heavily investing in modern machinery, including 4-axis and 5-axis CNC machining technology, advanced automated quality control systems, and continuously adopting cutting-edge technologies from abroad.

- Competitive production costs: Compared to China and other Southeast Asian countries, Vietnam currently has a competitive advantage in manufacturing costs in the international market due to lower labor costs while still maintaining high product quality.

- Government support policies: In today’s era of strong international integration, the Vietnamese government actively offers various tax incentives, financial support, and investment encouragement policies for the domestic CNC manufacturing industry.

- Capacity to fulfill large orders: Many CNC enterprises in Vietnam have expanded their production scale, improved quality, and effectively met the demands of large-volume orders from international customers.

1.2. CNC Enterprises Within Our Group

- TDB Hanoi Co., Ltd.: A specialist in manufacturing automotive and aerospace components, holding international certifications and exporting to the U.S.

- Matec Vietnam Co., Ltd.: Exports precision components for the supporting industries in furniture, construction, and consumer machinery sectors to Europe and the U.S.

- AMS Vietnam Technical Co., Ltd.: Certified with international quality standards such as ISO 9001 and AS9100, providing CNC machining services to major U.S. companies.

2. International Certifications Driving Vietnam’s CNC Exports to the US

2.1. ISO 9001:2015 – Quality Management Standard

ISO 9001:2015 helps Vietnamese CNC businesses enhance management efficiency, optimize production processes, and ensure products meet the strict requirements of international customers.

2.2. AS9100 – Certification for the Aerospace Industry

AS9100 certification allows Vietnamese CNC machining companies to enter the supply chain for the aerospace industry, meeting the highest standards of precision and product durability.

2.3. IATF 16949 – Certification for the Automotive Industry

IATF 16949 is a mandatory standard for CNC component suppliers in the automotive industry. Achieving this certification enables Vietnamese enterprises to easily access and participate in global supply chains, offering opportunities to collaborate with major U.S. corporations such as Ford, Tesla, and GM.

3. Future Prospects of Vietnam’s CNC Industry

- Increasing investment in new technologies: The adoption of AI, robotic automation, and IoT systems in CNC machining will enhance productivity and minimize errors in production processes.

- Expanding the U.S. market: Strengthening marketing efforts and participating in international trade fairs to attract U.S. customers to Vietnam.

- Collaborating with international partners: Strengthening relationships with major manufacturers from the U.S., signing long-term contracts to ensure a stable supply chain.

- Developing a domestic supply chain: Establishing a local raw material supply system to reduce dependence on imports and optimize production costs.

- Enhancing manufacturing standards: Obtaining additional environmental certifications such as ISO 14001 and ESG to meet the demands of customers from the U.S. and the EU.

With continuous advancements and a solidifying presence in the global market, Vietnam’s CNC industry is gradually proving itself as a key supplier for the U.S. market, creating numerous opportunities for future growth. Along with comprehensive strategic partnership agreements, the capabilities of Vietnamese enterprises, and the combination of skilled workforce, cutting-edge technology, and international certifications, Vietnam is poised to become an attractive destination for U.S. partners in the near future.

Proposed content

How CNC Machines Near Me Help Reduce Lead Times and Costs

How CNC Machining Services Support Sustainable Manufacturing Practices

Why Choose CNC Machining Suppliers in Vietnam Over China?

Whatsapp: +84345358698

No.03 Lot 8, Lai Xa, Kim Chung, Hoai Duc, Hanoi, Vietnam