Prototyping is particularly important in the contemporary world when developing new products because it provides a tangible representation of the proposed product. In the myriad of tools and techniques used to build prototypes, one protagonist has emerged, known as CNC (Computer Numerical Control) machining. Turning a product idea into a physical reality is made possible through Best CNC Machine Shops for high precision, versatility, and efficiency in prototyping.

What is CNC Machining?

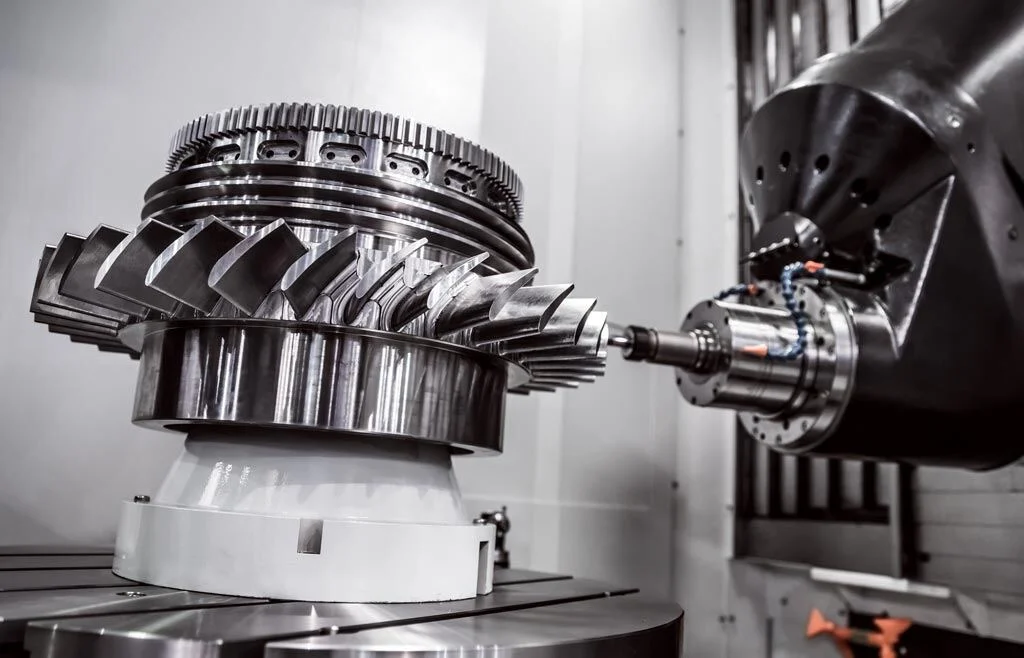

CNC machining means applying computer-controlled machines to cut, shape, and finish various materials, including metals, plastics, and timbers, to even complex structures. The process also provides high levels of Accuracy, and the ability to replicate this Accuracy is crucial in constructing prototypes that reflect the actual design. Millings, turning, drilling, and grinding operations are possible through CNC machines, a factor that makes the machines versatile for other products.

The Role of CNC in Prototyping

Precision and Accuracy There are a few drawbacks associated with CNC machining. One cannot minimize the use of this technology because of its unmatched precision and Accuracy when producing components with very close tolerances. Prototyping mostly requires generating intricate structures, requiring very high levels of Accuracy to fit. Another format provides for high Accuracy, which allows obtaining a prototype that is as close to the design as possible and up to minor details. Achieving such precision is important in determining the viability of the design and resource optimization for mass production.

Velocity and Efficacies CNC machines near me are reasonably faster than traditional manufacturing processes, which can involve hand operation or manual cutting. CNC machines can operate constantly and without supervision, considerably reducing production time. This makes CNC machining perfectly advantageous in rapid prototyping, which requires speed in testing and developing the final design. Besides, it is significant to understand that CNC machines can work on difficult contours and perform more than one operation in a single run.

Cost-Effective Custom Prototyping

Inexpensive for Small Parts Making Custom products typically entails creating smaller batches to trial different designs. As discussed earlier, using CNC machines is price-efficient in producing small batches since molds are saved, which is costly for other machinery like injection molding or die casting. One of the benefits of using CNC to create engineering parts is that it helps engineers make the final designs with minimal cost by reducing the amount of wasted parts that occur when designing for mass production during the design phase.

Work piece Flexibility: CNC machining services works with a broad range of materials, such as Aluminum, Steel, titanium, Plastics, Composites, ceramics, etc. This versatility allows the designer and engineer to use the material in question in an experimental manner and then choose the material most suited to the purpose intended for the product and the way the product is to be used. More importantly, prototypes developed using the final material better approximate the true test environment’s performance.

This paper aims to understand CNC machine shops’ role in production.

CNC machine shops play a critical role in the product development process of the end product. These facilities go beyond merely prototyping towards further optimizing the designs, evaluating the fit and functionality, and scaling up to full production. Engineers and machinists working in a CNC machine shop can make shared decisions more rapidly, with the least time wasted in tweaking or modifying prototypes in response to feedback or test outcomes.

In addition, CNC shops may have complementary goods and services, including three-dimensional scanning, engineering reversal, and post-processing, to complement the prototyping and design validation in creating prototypes. For instance, when a prototype has been built, as discussed above, it can be digitized to confirm that it meets the specified plans or used to create other digital images for the next prototype.

Conclusion

CNC machine shops are important in today’s prototype and product development industries. They introduced the designers to express ideas in a relevant, precise, quick, and cost-effective manner, making it easier to translate concepts to reality. From the assessment of the design fabrication, functionality testing, or even making modifications to prepare a product to be produced, it is clear that CNC machining plays this crucial role of making innovation faster and guaranteeing products are ready for mass production. With industry growth and heightened expectations from a short product development cycle time, computer numerically controlled machine shops will continue to play a central role in the prototyping process.

Related Categories: CNC Machining